DIGITALIZATION

Galvanizing Industry and Digitalization

In a rapidly advancing industrial landscape, digital transformation stands as a crucial element for growth and sustainability in the galvanizing sector. Digitalization not only enhances operational efficiency but also enables companies to meet the highest standards of environmental responsibility. By integrating advanced data analytics, real-time monitoring, and automation, the galvanizing industry is now setting new benchmarks for quality, safety, and sustainability, positioning itself as a forward-thinking sector in the global market.

In the galvanizing sector, embracing digital transformation is key to achieving operational excellence and sustainability. Through innovative technologies, galvanizing companies can optimize production, minimize waste, and strengthen their environmental commitments. With digital solutions such as predictive maintenance, real-time process monitoring, and advanced data analytics, the sector is poised to lead the charge in sustainable manufacturing.

1

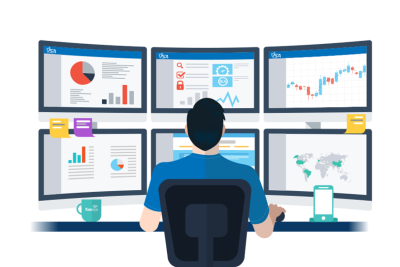

Enhanced Production Monitoring

Digitalization enables real-time monitoring of production lines, allowing galvanizing companies to keep track of operational status and identify inefficiencies immediately. Sensors and IoT (Internet of Things) technologies provide live data on temperature, chemical concentration, and energy use, ensuring processes stay within optimal parameters. This not only reduces waste but also helps companies maintain consistency and high quality in every batch.

2

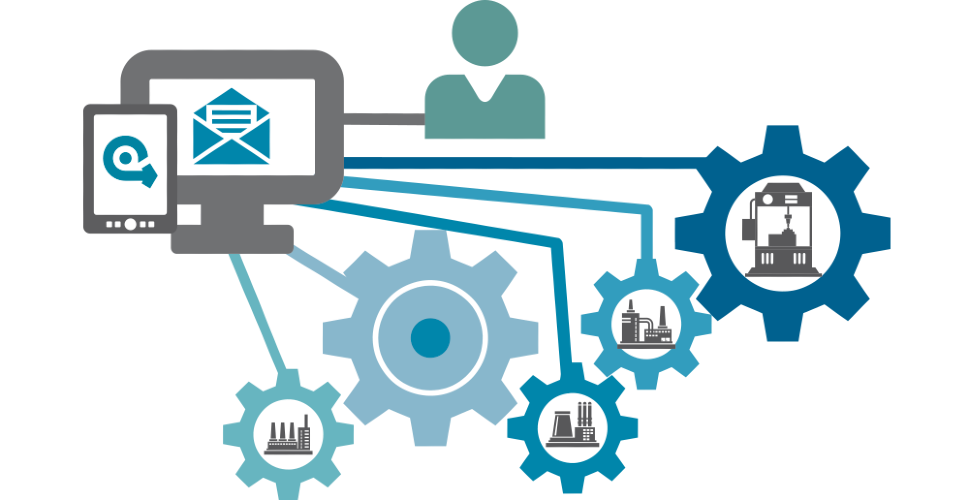

2. Optimized Inventory Management

Digital tools have revolutionized inventory management in the galvanizing sector, automating stock tracking and supply chain coordination. RFID tags and barcoding systems offer precise inventory levels and can even predict when supplies like zinc or acid need replenishing. By keeping optimal stock levels, companies avoid costly overstocking or production delays, leading to better resource allocation and minimized waste.

3

3. Predictive Maintenance and Equipment Longevity

By incorporating digital monitoring and predictive analytics, galvanizing facilities can better predict equipment maintenance needs before issues arise. Sensors continuously monitor the health of critical machinery, allowing companies to schedule maintenance during non-peak hours, reducing downtime and prolonging equipment life.

4

Data-Driven Quality Control

Dijital kalite kontrol sistemleri, kaplama kalınlığı, düzgünlük ve yapışkanlıktaki en ufak tutarsızlıkları bile tespit etmek için gelişmiş görüntüleme ve yapay zeka algoritmaları kullanır. Bu sistemler potansiyel kusurları hemen işaretleyerek malzeme israfını ve yeniden işleme ihtiyacını azaltır, böylece daha yüksek kalite ve çevresel ayak izinin küçültülmesi sağlanır.

5

Energy Efficiency and Environmental Monitoring

Energy-intensive sectors like galvanizing benefit greatly from digital solutions that monitor and control energy consumption. Advanced software can assess usage patterns and suggest optimizations to reduce excess consumption. Furthermore, digital emissions tracking allows for continuous air quality monitoring, ensuring compliance with environmental regulations and helping facilities stay within emission standards.

6

Digital Workforce Training and Safety Enhancements

Digital platforms and training simulations prepare staff with essential skills, reducing the learning curve and enhancing safety measures. Virtual reality (VR) training modules simulate galvanizing processes, giving employees hands-on experience without the associated risks. This improves workplace safety and ensures that workers are better prepared to handle critical situations.

7

Real-Time Compliance and Reporting

In an industry with strict regulatory standards, digital compliance systems simplify data collection, reporting, and audits. Automated systems collect and report environmental and operational data to help companies remain compliant with regional and international standards, enhancing transparency with both regulatory bodies and customers.

EST"GAL